Why it matters

This shielding material offers a durable, professional-grade solution to block, reflect, and minimise Magnetic fields, helping you create a calmer, lower-EMF environment.

Features & Benefits

Highly resistant with laminating film on both sides, suitable as an intermediate layer in roof or floor constructions.

Created from 6 very thin shielding foils together, because several thin layers provide better shielding than one thick sheet

Durable aluminium construction: Long-lasting, rigid, and corrosion-resistant - perfect for walls, floors, ceilings, or behind electrical panels.

Flexible installation: Can be mounted under plasterboard, in roof cavities, or used as part of an earthing system.

Non-toxic and maintenance-free: Safe for residential and commercial spaces.

Professional-grade performance: German-made and tested for consistent conductivity and shielding efficiency.

Available in different sizes on request

You are able to cut it into different sizes - But beware it becomes very sharp once cut!

Ideal for

Homeowners or renovators creating low Magnetic fields in bedrooms or workspaces.

Builders and electricians installing shielded Magnetic solutions.

People sensitive to electromagnetic exposure wanting extra protection.

Wellness-focused homes or clinics aiming for reduced EMF environments.

Technical data

Size: 80 x 55 cm (shielding surface); 82 x 57 cm (total product)

Thickness: 0.5 mm (0.7 mm overlapping)

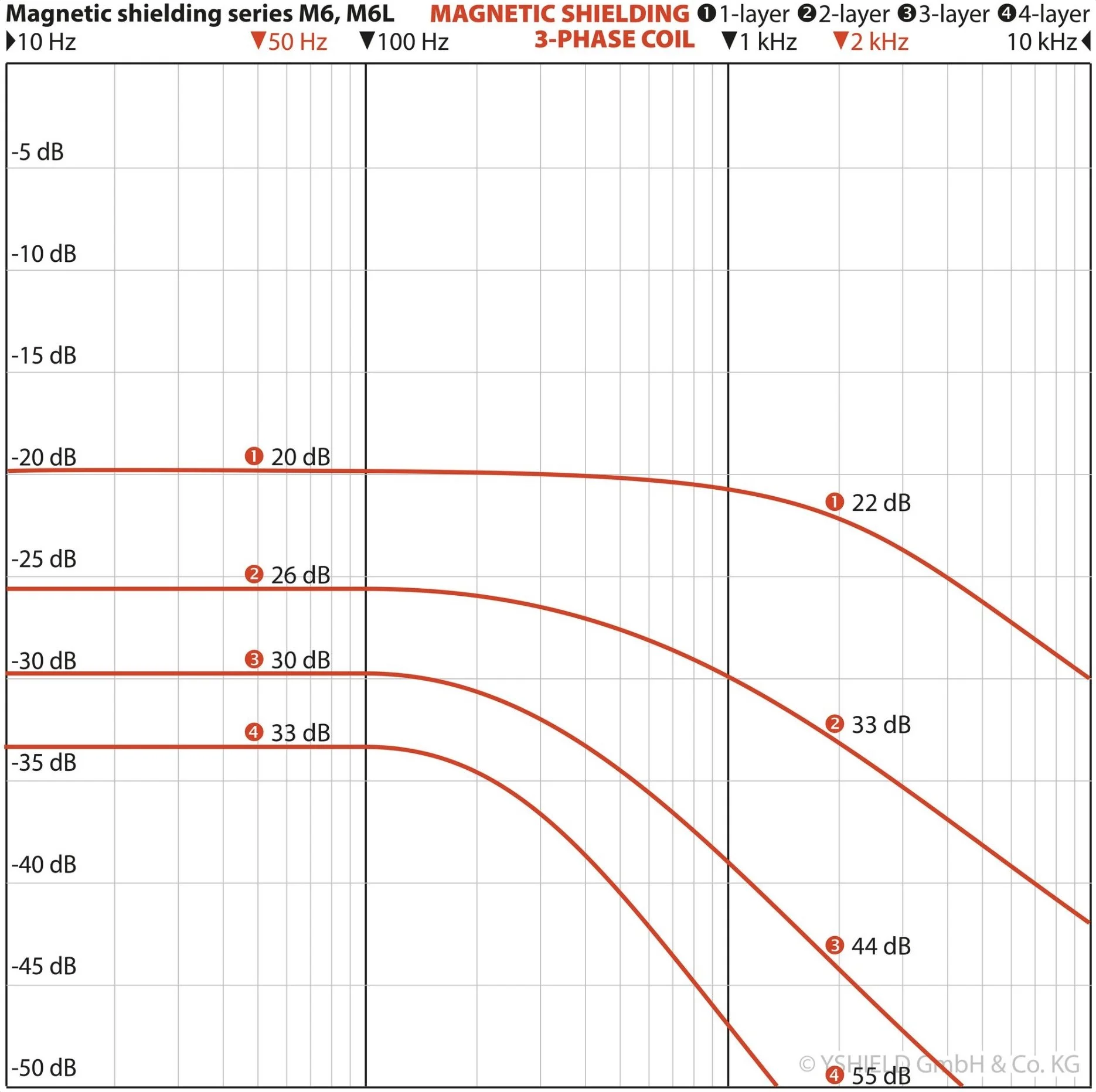

Attenuation magnetic fields (Three-phase 50 Hz): Single-layer 19.5 dB (89.4 %), two-layer 25.7 dB (94.8 %), three-layer 30.2 dB (96.9 %), four-layer 32.6 dB (97.7 %)

Attenuation magnetic fields (Single-phase 50 Hz): Single-layer 17.7 dB (87 %), two-layer 23.2 dB (93.1 %), three-layer 26.8 dB (95.4 %), four-layer 29.3 dB (96.6 %)

Attenuation magnetic fields (Static): DC consumers, earth magnetic field, permanent magnets are shielded in a range from 15 % (single-layer) to 58 % (four-layer)

Minimum bending radius: 20 cm

For reasons of innovation, we do not declare ingredients and magnetic key figures. The high-tech material has a high initial permeability and high saturation induction from 5 Hz.

Processing Attention: The M6L-series can be cut with high-quality scissors! The cutting edges are very sharp and need to be protected (eg with fabric tape) immediately after cutting! Use cut-resistant gloves during processing!

Processing with adhesive: Only a few adhesives can bond laminating film made of PET (polyethylene terephthalate). For secure bonding, we recommend our acrylate-based PSA adhesive, which produces permanently self-adhesive layers.

For wet bonding, work quickly and on small areas, then corrections can still be made. Non-absorbent substrates or multiple layers can be problematic because the solventcannot dry out due to the vapor-tight film! With dry bonding, you have an immediate, very strong adhesion that can no longer be removed. Application using a stapler or nailer: If the substrate is suitable, we recommend using an electric stapler or nailer. For one layer including overlap, a medium-priced electric tacker is sufficient; for two or more layers, you will need a professional nailer.

The shielding surface must overlap by at least 2 cm. Multilayer installation: Always install the plates in an offset position - the surface is to cover the overlapping underneath.

Grounding

When shielding magnetic fields, also pay attention to the electric fields. Grounding must be carried out to prevent the spread of electric fields. The M6L series is easy to ground. Contact us for further grounding advice.

Laboratory & expert report

Yshield invested in their own professional EMV laboratory years ago to create laboratory screening reports and check each batch daily. Additionally, they have all their products checked by independent, well respected experts.